Waveguide PPLN/PPLT Crystals

box:

HC Photonics - Waveguide PPLN/PPLT Crystals for higher efficiency wavelength conversion.Want to purchase this product?

Get in touch using one of the methods below

| Model | Title | Price |

|---|---|---|

| Default Title | PoR |

Summary box:

HC Photonics - Waveguide PPLN/PPLT Crystals for higher efficiency wavelength conversion.Description:

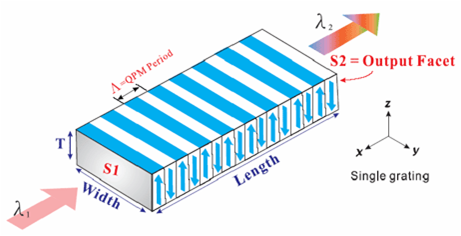

PPLN, PPLT waveguide chips provide conversion efficiency 2~3 orders of magnitudes higher than the conversion efficiency of the bulk chips. By combining the advantage of high intensity from channel waveguide (WG) structure and phase-matching/spectrum engineering from Quasi-phase-matching (QPM). Due to the tightly confinement of the waveguide structure, PPXX (PPLN, PPLT) waveguide chip is particularly suitable for high conversion efficiency applications, but normally with applicable power under sub-Watt level.

The waveguide can be manufactured on a periodically poled crystal to form a frequency conversion waveguide, such as PPLN waveguide in PPLN bulk crystal. PPLN bulk chips are easy to use and can handle higher optical power (up to a few Watts or more); PPLN waveguide chips provide much higher conversion efficiency and thus enable several applications beyond what can be realized by PPLN bulk (although with limitation in power handling and also challenging in practical alignment for coupling optimization).

- available for up-conversion (SHG/SFG) and down-conversion (DFG/OPA/OPG) frequency mixing configurations

- available for visible to mid-IR generation; also contact us for UV and THz

- available for uniform or chirped QPM structures

Please contact us to discuss the specifications and arrange a quotation.

Specifications:

| Serial # | pump λ (nm) | output λ (nm) | MFD(um2) | numerical aperture | propagation loss (dB/cm) | normalized efficiency (%/W/cm2) | Temperature slope (˘C/nm) |

|---|---|---|---|---|---|---|---|

| WG-B | 900-1000 | 450-500 | 4.90x4.09 | 0.13x0.15 | 0.9 (0.7) | 160 (250) | ~13 |

| WG-G | 1000-1200 | 500-600 | 4.90x4.09 | 0.15x0.17 | 1.0 (0.7) | 160 (200) | ~11 |

| WG-R | 1200-1400 | 600-700 | 5.56x4.30 | 0.15x0.20 | 1.0 (0.75) | 70 (80) | ~10 |

| WG-E | 1400-1600 | 700-800 | 5.62x4.31 | 0.18x0.23 | 1.0 (0.85) | 50 (65) | ~8 |

| WG-T | 1900-2200 | 950-1100 | 5.65x4.35 | 0.23x0.30 | 1.1 (1.0) | 20 (35) | 2.5-5.0 |