Summary Box:

DK-M3-RS-U-1M-20 and DK-M3-RS-U-2M-20-L developer kits for beam steering and mirror positioning provide convenient evaluation and prototyping of your design.Description:

M3-RS-U Rotary Smart Stages are ideal for beam steering and mirror positioning applications requiring precise, point-to-point positioning or dynamic scanning up to 100 Hz. These beam steering developer’s kits include mounted aluminum-coated mirrors with limit stops, for motion of +/- 20 degrees at up to 1100 degrees per second with accuracy of 0.25 degrees

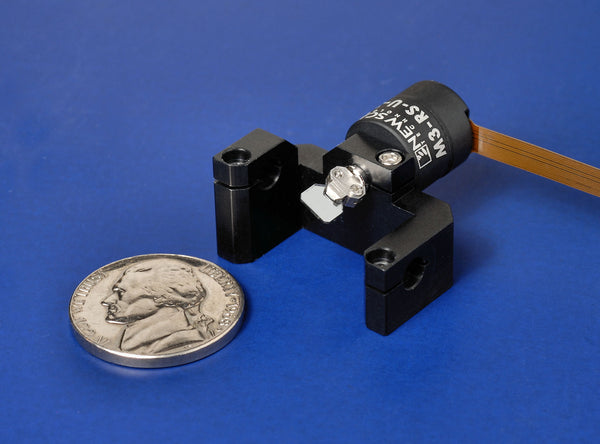

DK-M3-RS-U-1M-20

The developer’s kit for single-axis mirror positioning includes: one M3-RS-U-360 Rotary Smart Stage Positioning Module with embedded controller and straight FPC, one M3-RS-U-Mirror-01-03 mounted to stage, base, breakout board for testing and USB connection Cables and USB adaptor for PC control, New Scale Pathway™ Software.

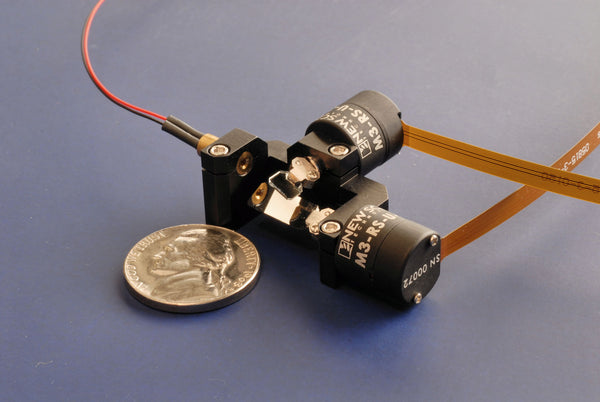

DK-M3-RS-U-2M-20-L

The Developer’s kit for two-axis, two-mirror beam steering includes: two M3-RS-U-360 Rotary Smart Stage Positioning Modules with embedded controllers and straight FPC, one M3-RS-U-Mirror-01-03 mounted to stage, one M3-RS-U-Mirror-01-11 mounted to stage, one 650nm collimated laser, base, demo board and cables for testing and USB connection, power supply, New Scale Pathway™ Software.

Specifications:

Performance for M3-RS-U Smart Stage with standard 3-mm long mounted mirror

| Beam diameter (max) | 2 mm |

|---|---|

| Range of motion | +/- 20 degrees (continuous 360 degree motion without mirror stops) |

| Speed | >1100 deg/sec |

| Acceleration | >1,000,000 deg/sec² (note 1) |

| Stall torque (min) | 0.04 N-mm |

| Holding torque (min) | 0.08 N-mm (zero power) |

| Recommended maximum payload mounted to rotating shaft (payload must be balanced) | |

| Mass | 3 g |

| Inertia | 350 g-mm² |

| CLOSED-LOOP performance (with built-in position sensor) | |

| Recommended step frequency | up to 100 Hz |

| Resolution (encoder resolution) | 0.025 deg (440 µrad) absolute |

| Repeatability | +/- 0.05 deg (880 µrad) |

| Accuracy | 0.25 deg (4400 µrad) |

| Maximum closed loop step & settle times (note 1) | 0.5 deg step: 9 ms 5 deg step: 14 ms 20 deg step: 21 ms |

| OPEN-LOOP performance (external position sensor provided by user) | |

| Resolution | <0.0057 deg (<100 µrad) |

| Accuracy | Typically better than 10% of distance travelled after calibration |

| Maximum open loop step times (note 1) | 0.05 deg step: 0.5 ms 0.5 deg step: 1.6 ms 5 deg step: 6 ms 20 deg step: 10 ms |

| Input voltage | 3.3 VDC |

| Power consumption (typical) input directly to stage |

500 mW active, moving 190 mW active, ready 50 mW standby |

| Power consumption (typical) input via USB interface |

BREAK-OUT BOARD (one-axis developer's kit) 675 mW active, moving 365 mW active, ready 150 mW standby – DEMO BOARD (two-axis developer's kit) 1200 mW active, both axes moving 580 mW active, ready 200 mW standby |

| Stage mass | 3 g |

| Operational lifetime | 100 million random positions |

| Temperature and relative humidity | 0 to +60 °C, non-condensing |

| Conformance | CE / RoHS |

| Controller | Integrated into stage, 64 MIPS no external controller needed |

| Communication interface | I²C, SPI, UART or analog servo Input directly to M3-RS |

Note 1: With 0.99 g-mm2 inertial load of standard mounted mirror M3-RS-U-Mirror-01-11

Internal Stage …..0.39 g-mm2

Mirror Clamp …… 0.45 g-mm2

Mirror ………… 0.15 g-mm2

———————————–

Total Inertia…… 0.99 g-mm2

Standard Mirror (included in the Beam Steering Developer’s Kits)

| Size – M3-RS-U-Mirror-01-03 (included in both dev kits) | 3 x 5 x 0.4 mm |

|---|---|

| Size – M3-RS-U-Mirror-01-11 (included in two-axis dev kit only) | 11 x 5 x 0.4 mm |

| Material | float glass |

| Coating | protected aluminum (MgF2) |

| Operational bandwidth | 0.350 – 4.0 μm |

| R(avg) reflectivity (0.350 – 4.0 μm) | 90% |

| Max beam diameter | 2 mm |

| Flatness (632 nm) | lambda/4 over any 2 mm length |

| Surface quality | 60 – 40 scratch / dig |

| CW damage threshold (4 μm) | 6 W/cm² |

| Pulsed damage threshold (1 μsec pulses, 35 nm, 20 Hz) | 0.3 J/cm² |